Plaster Concentrate

Everything a readymix plaster should be.

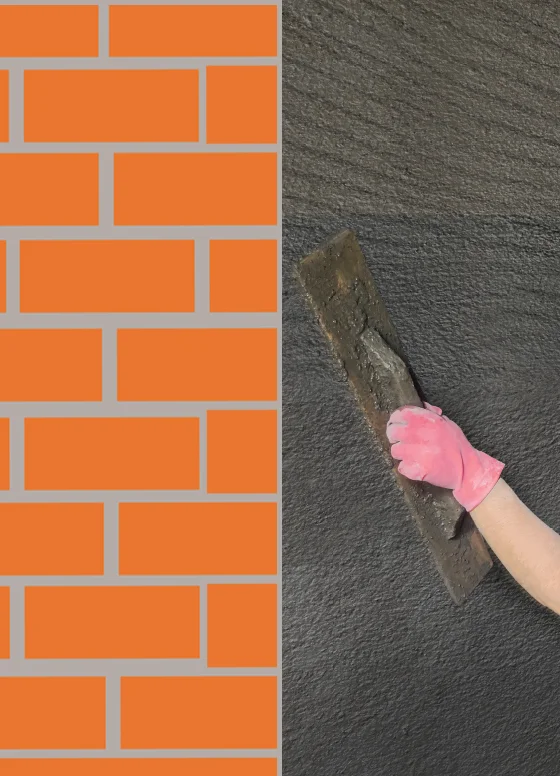

Say goodbye to messy, time consuming sand-cement plastering! Made from high quality additives, EnvoPlast is a unique ready mix cement plaster that can be used with equal effectiveness on brick, block, stone or concrete surfaces. With its even surface, smooth finish, and superior binding, EnvoPlast provides the ideal surface for tiling. Its unique mix of special binders and additives, make it resistant to water and also reduce the chances of cracks developing in the plaster, in comparison to conventional plasters.

Unlike conventional plasters, EnvoPlast contains no river sand and, thus, no silt or other organic matter, giving it unbeatable crack-resisting properties. In addition, the uniformity in size and structure of the sand grains used ensures compactness and consistency in quality throughout the project.

EnvoPlast is manufactured under stringent ISO certified quality control systems that assure a predictably superior performance on a variety of surfaced, internal and external.

Like all other products manufactured by R. D. Ventures, EnvoPlast stands by the brand’s values of recycle, reuse and regenerate. It is a certified green material, containing > 75% recycled ingredients, such as fly ash, processed waste sand.

Application

Mixing

Prepare the plaster by mixing 7-10 liters of water per every 50 Kg bag of EnvoPlast. Use of mechanical mixer-electrical stirrer is recommended for better results. Mixing should be done for 5-10 minutes depending upon the speed of mixing equipment. When the mixture is prepared, leave it for 5 minutes and mix it once again just before use. Do not add any water to the mixture at this point of time. Hard and set plaster should not be mixed again. The correct ratio of water and EnvoPlast is essential for best results.

Surface Preparation

The surface should be free of dust, grease etc., else it will affect binding. If the surface is dry, it should be moistened with clean water.

Applying to the surface

- The mixture should be applied within 1-2 hour of preparation. If the concrete surface is smooth and dense, it’s recommended that the surface is made rough with a comb for better sticking of the plaster layer.

- If it is to be used on AAC blocks, concrete blocks or concrete surfaces, ensure to apply cement slurry before plastering.

- Spread the mixture evenly for a smooth finish.

- You only need to maintain a thickness of 6 to 12 mm to avoid any cracks being formed. Do not exceed this thickness.

- For optimum results, cure two to three times for five to seven days.

Curing/Saturation

Different finish can be obtained by using trowel for smooth finish, sponge for rough finish and spray can for dotted rough finish.

Use Cases

Stone walls

AAC Blocks

Brick

Concrete Blocks

Why construction engineers prefer Envoplast?

Time Savings

Money Savings

High Quality Additives

Easy Application

Even Finish

Least Rebound

No Silt—No Cracks

Green Building Material

Assured Quality and Durability

Technical Description

| Appearance | Grayish granular powder |

| Main Binder | Portland Cement |

| Aggregate | Graded Sand |

| Additives | Water soluble additives for better efficiency, binding, water retaining and strength |

| Maximum Aggregate Size | Less than 4.75 mm |

| Bulk Density | 1.2 – 1.6 Kg/liter unit |

| Compressive Strength (mpa) | More than 5 in 28 days |

| Coverage | 0.16-0.23 Kg/sq.f./mm** (for 10mm thickness/ 25 sq.ft) |

| Thickness of Layer | 6-12 mm |

| Pot Life | 1-2 hours |

| Water Proportion (%) | 15% to 20% of the weight |

I’m Interested. Tell me More

Head Office Pune

Samarth Tarrace, Flat no.1, Vimannagar Ganpati Chowk, Near Air Force Station, Vimannagar, Pune 411014

For Mumbai Enquiry

Contact Mr. Shailendra Tiwari

- +91 84548 41354

sales@envoplast.in

Phone

+91 9960383838 | +91 9823025484 | +91 35918083